Simply “tilting the frying pan” will not fully demonstrate the performance of this machine. It seems like something he'd buy on QVC to make the perfect Belgian waffle, but it's actually huge. It is a 45-ton pressure cooker that is 4 feet wide and 3 feet deep with a 45-gallon tub that rotates on a horizontal axis. . The tilt function allows you to easily collect cooked food onto the tray.

“These are extremely important to our business,” Perez said in early March, standing next to the refurbished cookers.

“You can steam, grill, or fry just about anything with it,” Perez says. “Cooking a 50-pound bag of beans will take about 30 minutes.”

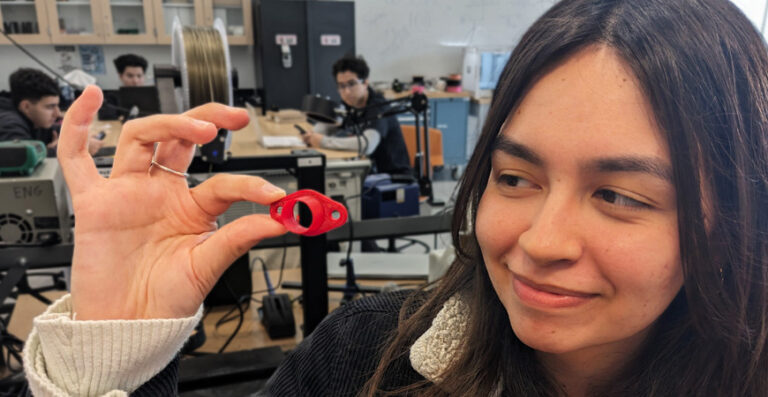

Back in January, kitchen staff noticed that the lid on one tilt skillet was not securing properly. The dining facilities team was called and found the bushing broken in two inside the handle latch. They went online to order replacement parts but couldn't find anything. That part was no longer made.

So Perez turned to the idea of recreating the parts with a 3D printer. He first turned to Sean Pamar, director of information technology procurement in the university's Supply Chain Center of Excellence. He knew Pamer was his 3D printing enthusiast.

“I asked him, 'Can you do it?' He said, 'Let's try,'” Perez said.

Oz Smith, a maintenance mechanic at Dining Services, shared a photo of the broken part and a sketch depicting its dimensions. Pammer researched what a printed alternative would entail. He had the tools to remove it, but the plastic needed was expensive and not readily available.