Researchers at the University of Michigan have developed a memristor with tunable relaxation time, which could lead to more efficient artificial neural networks capable of time-dependent information processing.

Published in Nature ElectronicsThe work highlights the potential of memristors, electronic components that can act as memory devices and retain their resistance state even when power is removed.

Memristors work by mimicking key aspects of how artificial and biological neural networks function without any external memory. This property has the potential to significantly reduce the energy demands of AI, which is important as the technology's power consumption is predicted to increase significantly over the next few years.

The Kitchen Sink of the Atomic World

“Right now there's a lot of interest in AI, but the approach is to increase the size of the network to process larger and more interesting data, which is not very efficient,” said Wei Lu, UM's James R. Mellor Professor of Engineering and co-corresponding author of the study with John Herron, UM associate professor of materials science and engineering.

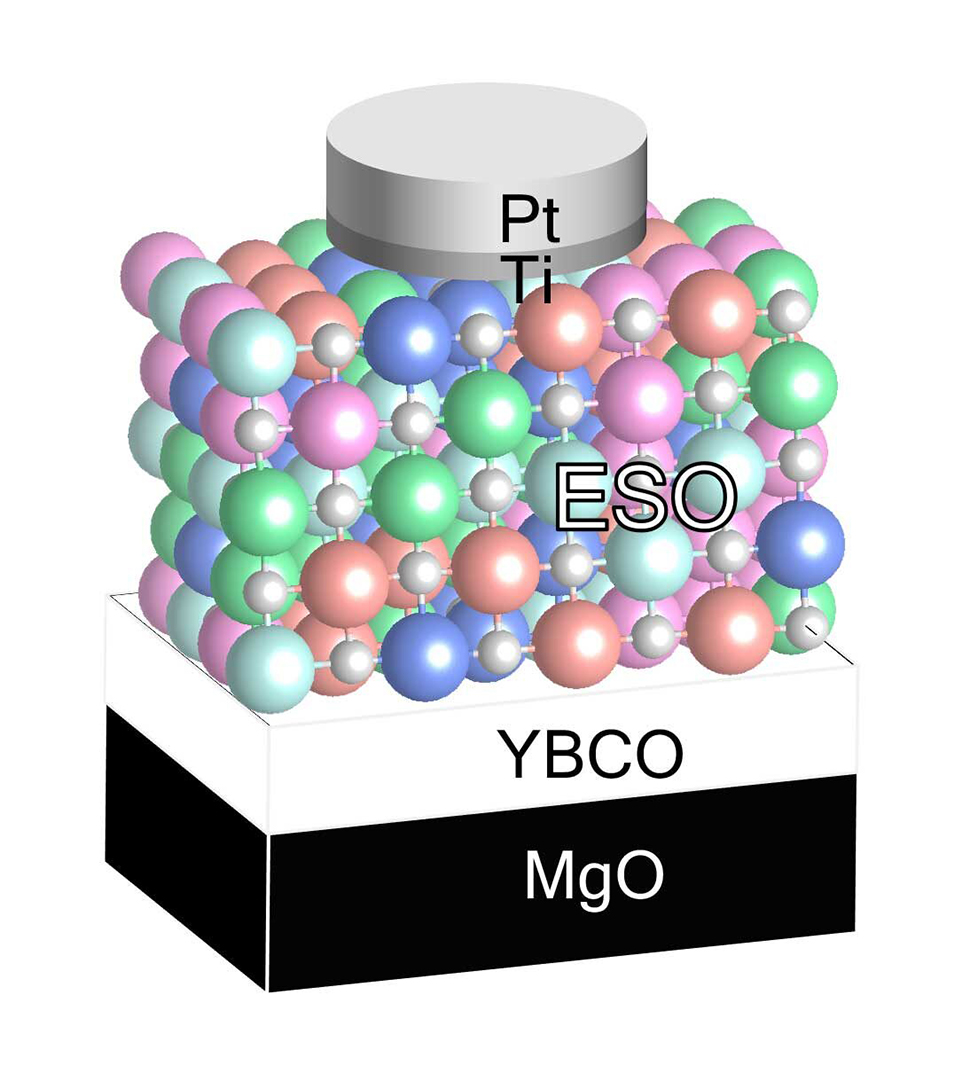

The team achieved tunable relaxation times in their memristors by varying the ratio of base materials in the superconductor YBCO. Made of yttrium, barium, carbon, and oxygen, this superconductor has a crystalline structure that guides the organization of other oxides in the memristor material.

Heron calls these entropy-stabilizing oxides “the kitchen sink of the atomic world,” because the more elements that are added, the more stable they become.

By varying the ratio of oxides, the team achieved time constants ranging from 159 to 278 nanoseconds. They then built a simple memristor network that could be trained to recognise the sounds of the digits from 0 to 9. Once trained, the network was able to identify each digit even before voice input was complete.

The findings represent a major step forward in neuromorphic computing: memristor-based networks could dramatically improve the energy efficiency of AI chips by as much as 90 times compared to current GPU technology. “For now it's just a vision, but we think there are ways to make these materials scalable and affordable,” Heron says. “These materials are Earth-abundant, non-toxic, inexpensive, and you can pretty much spray them on.”